Charlotte, NC — F. D. Hurka Metrology, a precision measurement company based in Charlotte, NC, offers dedicated consulting services to help manufacturers make ideal decisions when selecting a coordinate measuring machine (CMM). With more than 50 years of experience and an ISO 17025:2017-accredited lab, the company provides industry-specific guidance on CMM selection, implementation, and optimization.

Proper CMM Selection Boosts Manufacturing Quality

Choosing the right coordinate measuring machine impacts accuracy, production speed, and long-term cost control. F. D. Hurka Metrology helps clients identify the CMM products best suited to their part sizes, tolerances, and workflow requirements.

Manufacturing facilities often struggle with CMM selection because they focus solely on technical specifications without considering integration challenges, operator training needs, and long-term maintenance requirements. F. D. Hurka Metrology's consultation process evaluates these practical considerations alongside technical capabilities, including assessment of existing quality control procedures and analysis of future growth plans.

Industry-Specific CMM Solutions

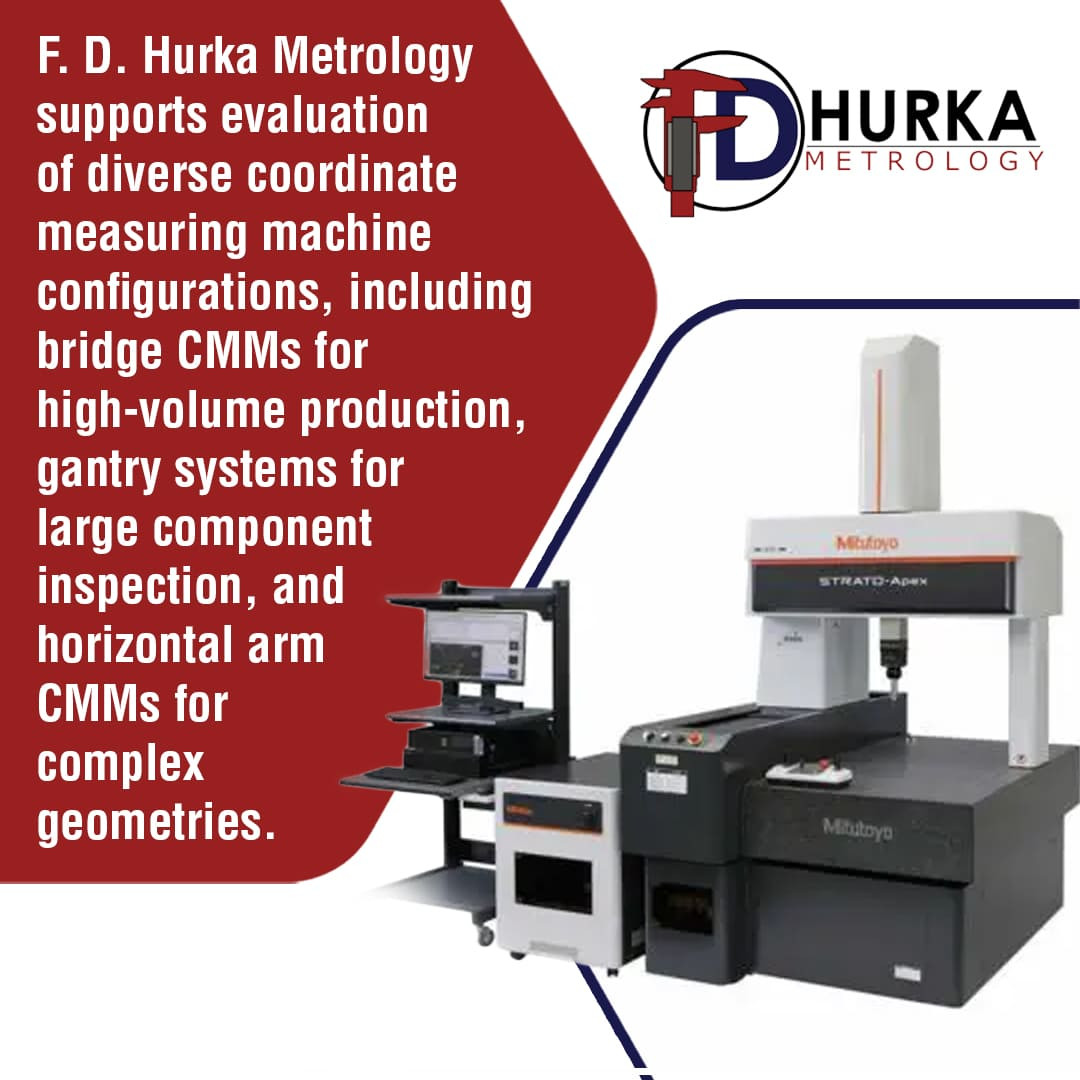

F. D. Hurka Metrology supports evaluation of diverse coordinate measuring machine configurations, including bridge CMMs for high-volume production, gantry systems for large component inspection, and horizontal arm CMMs for complex geometries. Each configuration offers distinct advantages for specific manufacturing applications.

Automotive Manufacturing Applications

Automotive manufacturers typically require CMM systems that integrate with statistical process control networks and handle rapid inspection cycles. These facilities benefit from coordinate measuring machine solutions that support automated measurement protocols and real-time quality monitoring. The company helps automotive clients select systems with the following capabilities:

High-speed measurement cycles for production line efficiency

Statistical process control integration for real-time quality monitoring

Large measurement volumes for body panels and chassis components

Multi-probe systems for engine and transmission housing inspection

Automated measurement protocols to reduce operator intervention

Aerospace Industry Requirements

Aerospace applications demand coordinate measuring machine systems capable of measuring complex airfoil profiles, bolt hole patterns, and assembly tolerances with exceptional accuracy. F. D. Hurka Metrology guides aerospace manufacturers through CMM selection processes that ensure compliance with strict industry standards and traceability requirements.

Key aerospace CMM selection criteria include:

Ultra-high accuracy for critical safety components

Advanced probe systems for complex geometric measurements

Detailed documentation and traceability capabilities

Environmental compensation for temperature and vibration control

Specialized software for airfoil and surface profile analysis

Medical Device Precision Standards

Medical device manufacturers face unique challenges requiring cleanroom-compatible coordinate measuring machine systems with ultra-precise measurement capabilities. The company assists medical device clients in selecting CMM products that meet biocompatibility requirements while delivering the accuracy needed for implant devices and surgical instruments.

The evaluation process also addresses probe system selection, measurement software capabilities, and data management requirements. Modern CMM products offer sophisticated programming interfaces and automated measurement routines that greatly reduce inspection time and operator training requirements.

Environmental and Operational Considerations

Environmental and operational considerations play critical roles in successful CMM selection. F. D. Hurka Metrology evaluates facility conditions, including temperature control, vibration isolation, and power quality requirements. Coordinate measuring machine performance depends heavily on environmental stability, making proper installation planning essential for achieving specified accuracy levels.

Critical Facility Requirements

The company's extensive facility assessment addresses multiple environmental factors that directly impact coordinate measuring machine performance:

Temperature control systems maintaining stable thermal environments

Vibration isolation foundations preventing external interference

Clean electrical power supplies with proper voltage regulation

Compressed air systems for pneumatic components and probe changers

Adequate floor space and structural support for large CMM products

Implementation Support Services

The company's contract inspection lab services provide clients with hands-on experience using different CMM products before making final selection decisions. This practical evaluation approach allows manufacturers to assess system performance with their actual components and measurement requirements.

F. D. Hurka Metrology offers full implementation support, including:

Pre-installation facility assessment and preparation guidance

Equipment evaluation using actual client components

Operator training programs covering system operation and programming

Calibration services ensuring measurement accuracy and compliance

Ongoing technical support throughout the equipment lifecycle

Why trust F. D. Hurka Metrology?

Serving manufacturers since 1970, F. D. Hurka Metrology has established relationships with leading coordinate measuring machine manufacturers while maintaining independence in equipment recommendations. This position allows the company to provide unbiased guidance focused on client needs rather than vendor preferences.

The company's ISO 17025:2017-accredited laboratory demonstrates commitment to measurement accuracy and quality standards. Clients benefit from access to calibration services, training programs, and ongoing technical support that extends well beyond initial CMM selection and installation.

About F. D. Hurka Metrology

F. D. Hurka Metrology, located in Charlotte, NC, specializes in precision measurement solutions for manufacturers across industries. The company provides coordinate measuring machine services, contract inspection, calibration, and consultation. Its ISO 17025:2017-accredited lab supports clients with advanced metrology equipment and industry expertise. Contact F. D. Hurka Metrology to know more about their CMM selection guidance and precision measurement services.